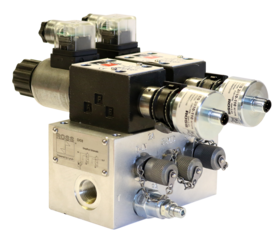

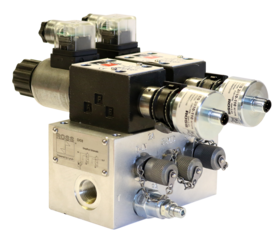

Hydraulic safety valves by Ross are perfect for external monitoring

Advanced Motion & Controls Ltd. supplies two series of Ross hydraulic safety valves.

Advanced Motion & Controls Ltd. supplies safety valves by Ross Controls, a manufacturer in Troy, MI. This includes two types of hydraulic safety valves, which are redundant-valve systems designed for external monitoring applications. Ross produces block-and-bleed valve systems and block-and-hold valve systems.

Both types of Ross valves are base-mounted and have a tamper-resistant design. They are also equipped with position sensors for external monitoring by an electrical safety control system.

Multiple features and benefits

Ross’ HBB series of block-and-bleed hydraulic safety valves are redundant 3/2 systems built to meet the requirements of safe hydraulic block-and-bleed applications. They are ideal for up to Category 4, PL e, and SIL 3 applications when implemented into a system properly. Horizontal orientation is preferable.

Constructed out of ductile iron, steel, and Buna-N, these are safe-supply/exhaust double valves that can flow up to 50 gallons per minute (gpm) of liquid. Three types of body sizes are available – D03, D05, and D07 – as well as post sizes of SAE-8, SAE-12, and 1¼, Code 61 Flange. These valve systems also have relief valves on the inlets.

Other specifications for HBB valves: a spool-type construction design; one solenoid per valve element (users must operate solenoids synchronously); power consumption of 30 watts per solenoid, or 36 for the D05; recommended temperature range from -20 to 71 degrees Celsius (ambient) or up to 60 degrees Celsius (media); and maximum inlet pressure of 5,000 pounds per square inch.

Also available from Advanced Motion & Controls Ltd., the HBH series of block-and-hold valve systems are load-holding double valves available in two body sizes, D25 and D32. These hydraulic safety valves can flow up to 145 gpm and have port sizes of 1½ and 2, Code 62 Flange. They are redundant blocking valve systems designed specifically for critical applications in which safe load holding is necessary for hydraulically controlled cylinders.

Useful for Category 4 and PL e applications when properly implemented into the system, these valves have specifications similar to those of the block-and-bleed ones, but with power consumption of 30 watts per solenoid.

To learn more, contactAdvanced Motion & Controls.