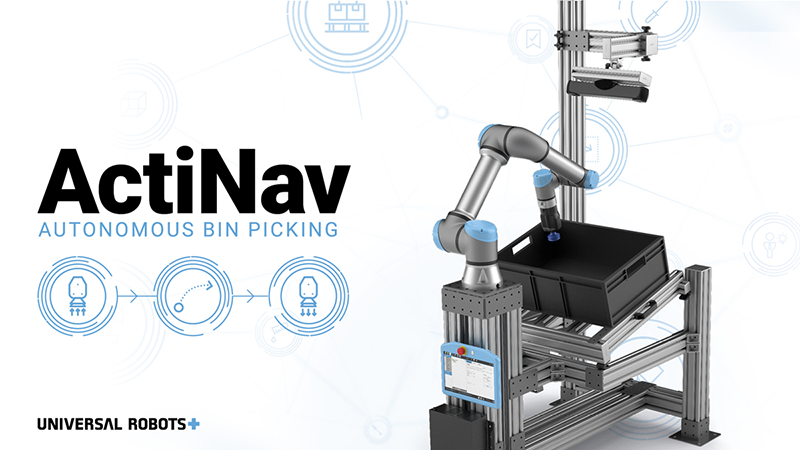

ActiNav – Next Generation Machine Loading

ActiNav™ combines intelligent vision, real-time autonomous motion control and Universal Robots’ world-leading cobots to deliver the core of a machine loading system. Whether used for simple bin picking tasks or more complex machine tending applications, ActiNav delivers a solution that’s precise, consistent, intuitive and more agile than ever before.

Plan, pick and place parts with some of the highest accuracy, without collisions and without the need to stop – optimizing machine uptime and boosting productivity.