Flexible feeding systems by Asyril handle parts of any geometry

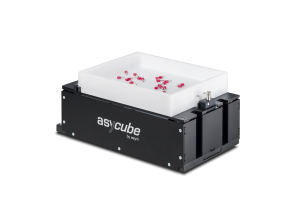

Asyril’s Asycube flexible feeding system

Advanced Motion & Controls Ltd. teams up with many major manufacturers to bring the best industrial equipment to Canadian businesses. One of these producers, Asyril, is renowned for its high-performance flexible feeding systems that work with parts and components measuring up to 40 millimetres (mm) in size.

With innovative technology, Asyril’s flexible feeding systems allow for very gentle feeding for all parts, regardless of the geometry.

Seamless integration with UR cobots

The Asyril team’s ability to blend its extensive knowledge and collective experience in vibration technology, industrial vision, and precision robotics is evidence of its special skill and focus. With this unmatched mix of capabilities, the company delivers superior feeding systems that meet the automation challenges of today and the future. These systems are all Swiss-produced, which not only ensures top product quality, but also gives customers a long-lasting, future-proof competitive advantage and a quick return on investment.

One example, the Asycube, is a three-axis vibration robotic parts feeder that offers pre-orientation and maximum surface distribution and can feed components of any shape, material, or size from less than one mm to 15 centimetres. Asyril recommends these feeders for applications in which parts are delivered in bulk and must be presented one at a time. Pick-and-place tasks, machine tending, assembly, CNC machining, and packaging/palletizing are common applications.

Asyril flexible feeding systems work well with collaborative robots. Last year, the manufacturer launched the URCaps plugin, designed specifically for the Universal Robots (UR) Solutions platform. UR robots, or “cobots”, are also available from Advanced Motion & Controls Ltd., and this plugin makes cobots operate even more smoothly, with a seamless, fast integration of any Asycube feeder in conjunction with any cobot device.

Other user benefits of the Asycube:

- fewer production changeover times.

- high reliability and durability.

- precise part detection.

- systematic part orientation.

- easy communication with different automation systems

For a look at another major Asyril product, the Asyfeed Pocket Module Pins Demo, check out this video:

For more information, contact Advanced Motion & Controls.